NEWS

Latest Product

Contact Us

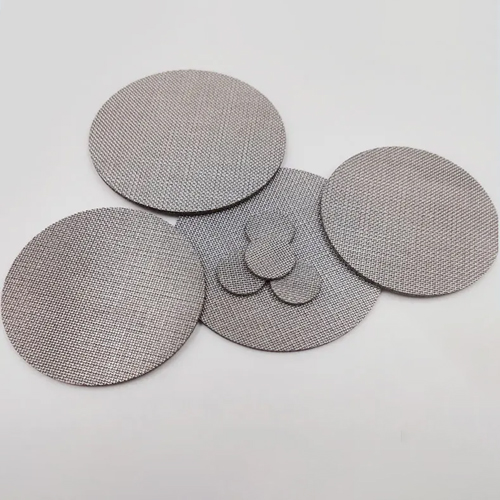

The Main Features Of Stainless Steel Filtering Screens

2024-08-08Stainless steel filtering screens are widely used in various industries due to their excellent characteristics.

The main features of stainless steel filtering screens:

High Corrosion Resistance: Made of stainless steel materials, they have excellent resistance to corrosion from acids, alkalis, and other chemical substances. This allows them to maintain stable performance and a long service life even in harsh chemical environments.

Good Filtration Accuracy: They can achieve precise filtration by controlling the mesh size and structure. Whether it is for filtering fine particles or large - sized impurities, stainless steel filtering screens can effectively separate the target substances according to the required filtration accuracy.

High Strength and Toughness: Stainless steel has high strength and toughness, so the filtering screens made of it are not easy to deform or break under high - pressure or high - load conditions. This ensures the stability and reliability of the filtration process.

Excellent Heat Resistance: They can withstand high temperatures and maintain their shape and performance. This makes them suitable for use in high - temperature environments, such as in some industrial processes involving hot fluids or gases.

Easy to Clean and Maintain: The smooth surface of stainless steel filtering screens is not prone to adhesion of substances, and it is easy to clean with water or other cleaning agents. Regular maintenance can keep the filtration efficiency and performance of the screens in good condition.

Long Service Life: Due to their high corrosion resistance, wear resistance, and other properties, stainless steel filtering screens have a long service life, which can reduce the frequency of replacement and save costs in the long term.

Wide Range of Applications: They are widely used in many fields, including the food and beverage industry, pharmaceutical industry, chemical industry, water treatment, and petroleum industry. They can meet the different filtration needs of various industries.

Chinese

Chinese